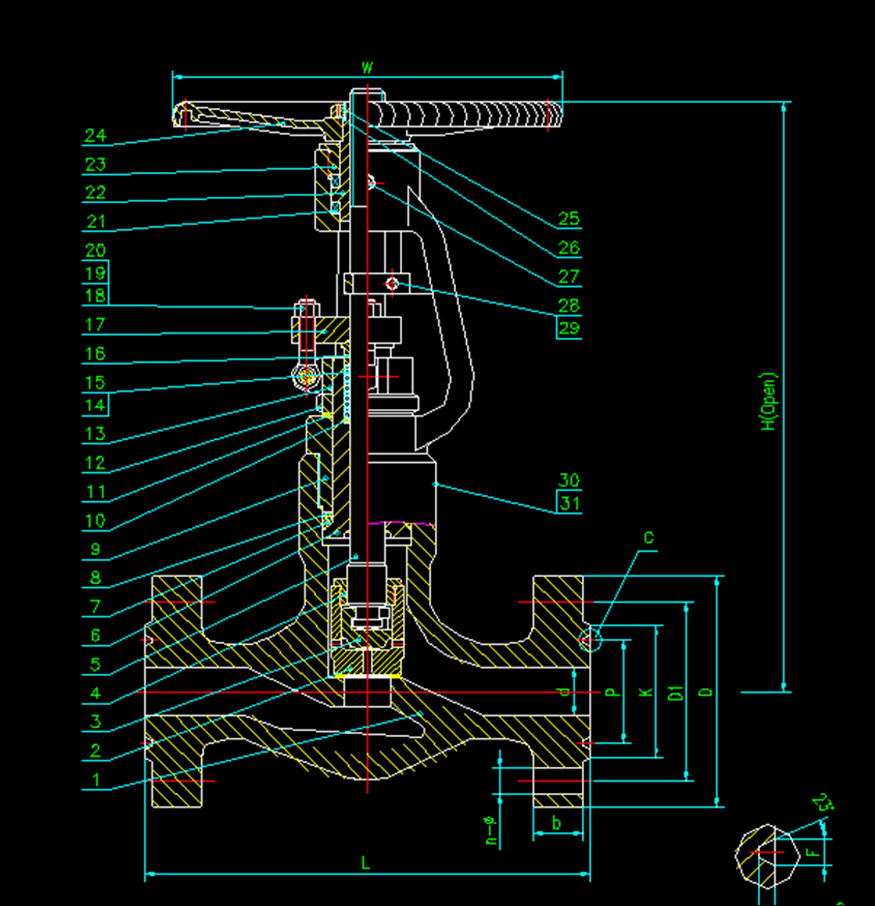

The RAYS pressure sealed globe valve can ensure good sealing performance under high temperature and high pressure conditions. When the RAYS pressure sealed globe valve is working, the stuffing box faces one end of the valve disc and protrudes out of the valve cover which forms an end diameter larger than its diameter. The inverse taper for the diameter of the fitting section with the valve cover is set in the annular gap formed between the conical surface of the reverse taper on the stuffing box, the inner hole of the valve body and the end surface of the valve cover facing the inside of the valve. This corresponds to the shape of the gap sealing ring. Using the above technical scheme, the pressure of the liquid medium itself is used to achieve the purpose of sealing. When the pressure fluctuates, the sealing performance is good and the sealing is reliable.

Pressure sealed globe valve is suitable for class 600(PN100)~2500(PN420 and working temperature -60℃~538℃ pipeline. Using carbon steel, stainless steel, and other different main materials can be suitable for various media.

It can be used in tap water, sewage, construction, food, electricity, medicine, metallurgy, textile, energy and other fluid pipelines for cutting, adjustment, & throttling. It is generally connected to the pipeline by flange connection or welded connection. The optional drive devices are: hand wheel, bevel, gear, electric, pneumatic, etc.

Applicable Standards:

●STEEL GLOBE VALVES, BS EN 13709/API 600

●STEEL VALVES,ASME B16.34

●FACE TO FACE, ASME B16.10

●END FLANGES ASME B16.5

●BUTTWELDING ENDS,ASME B16.25

●INSPECTION AND TEST, API 598

Design descriptions:

●PSB,PRESSURE SEAL BONNET

●OS&Y, OUTSIDE SCREW AND YOKE

●BB, BOLTED BONNET

●RENEWABLE SEAT RINGS

●RISING STEM AND HANDWHEEL

●FLANGED OR BUTTWELDING ENDS

●AVAILABLE WITH BG OPERATOR