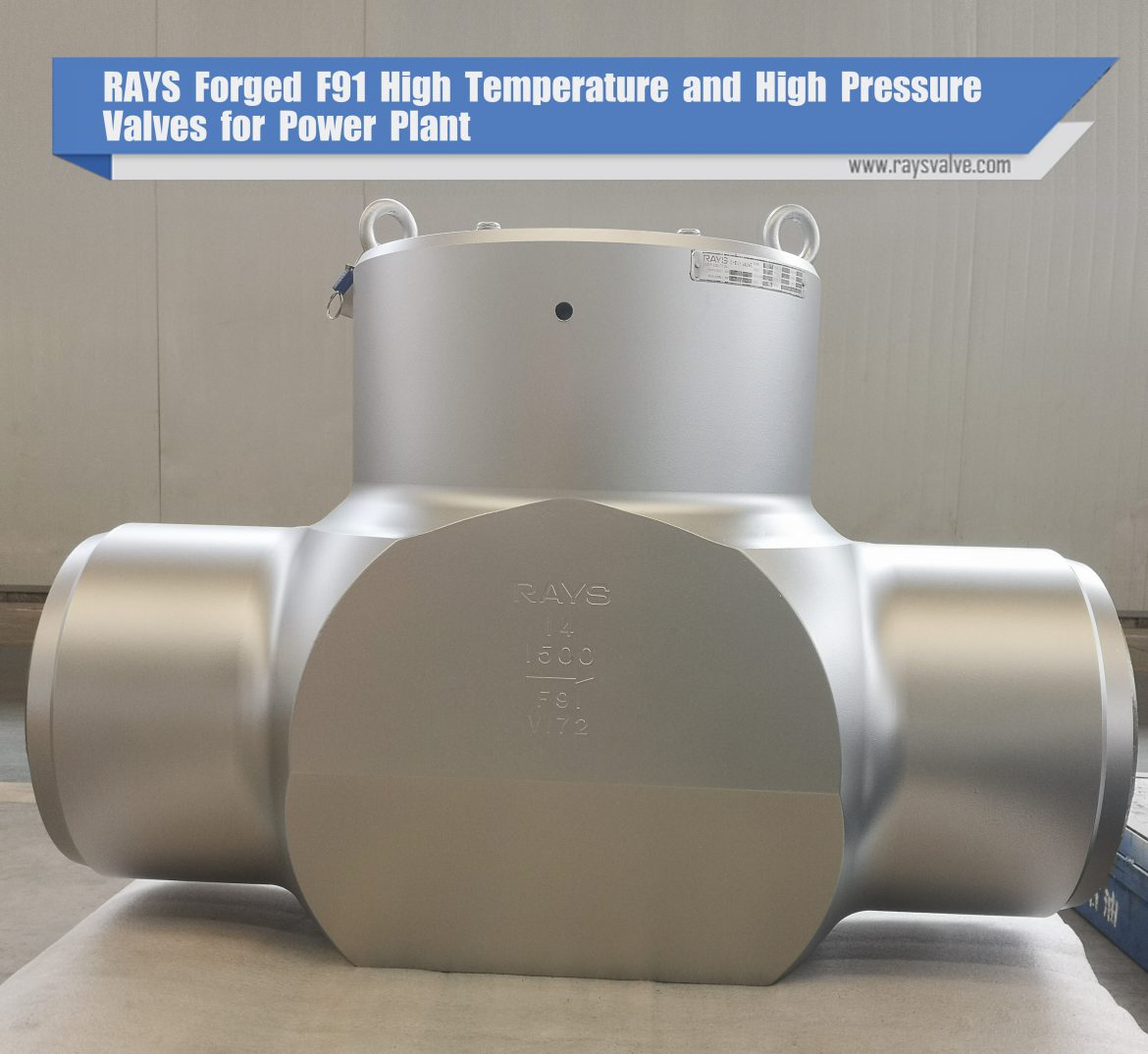

RAYS recently delivered high pressure and high temperature gate valves and check valve for the project based in Malaysia.

The middle cavity of the valve adopts a pressure self-tightening sealing structure. The higher the inner cavity pressure, the better the sealing performance. Both ends of the branch pipe are welded structures, which are suitable for different connection requirements.

The sealing surfaces of the gate and valve seat are made of stellite cobalt-based cemented carbide, which has: good wear resistance, high temperature resistance, corrosion resistance and scratch resistance.

The valve stem is quenched, tempered and surface nitride. This creates good corrosion resistance and scratch resistance. The structure of the opening and closing parts can be designed into different forms such as single board, double board, parallel double board and so on according to user requirements.

The gate valve connected by welding is suitable for cutting off or connecting the medium on the pipeline of various working conditions such as petroleum, chemical industry, thermal power station, etc. This is with a nominal pressure of 16.0-32.0Mpa and a working temperature of ≤540 °C.