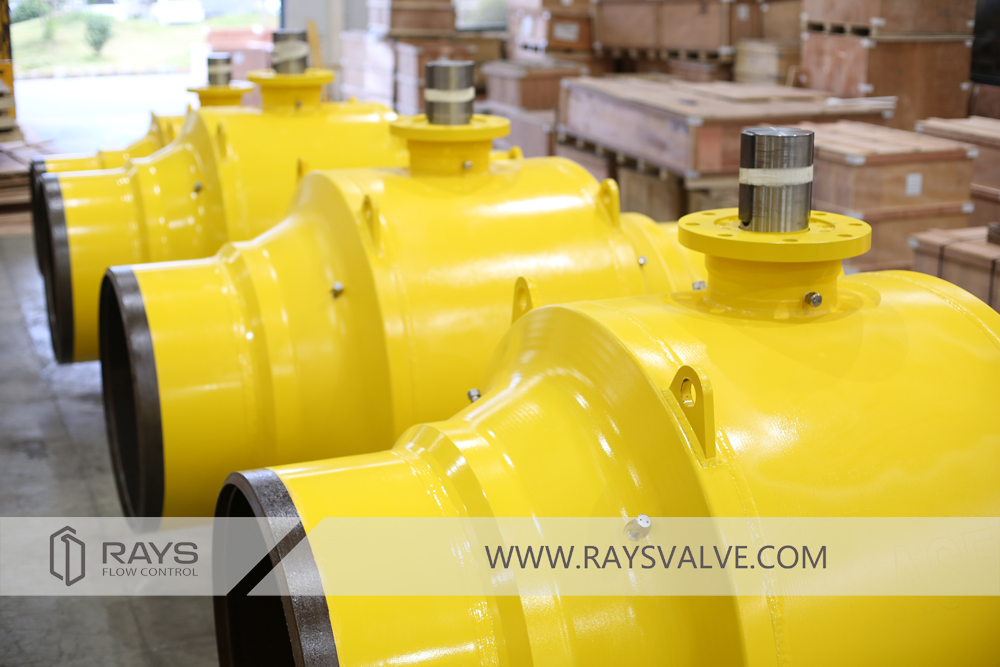

Recently,RAYS have successfully completed four pcs of fully-welded ball valves withspecifications of 32″ CL600 and 40″ CL600, which had passed varioustests and finished painting. They will be delivered to an internationalcustomer later this month and put into use within a large-scale natural gasproject.

- Due to the ball valve adoptinga fully-welded structure, the overall leakage point is very little whichgreatly reduces the risk of leakage.

- The valve stem is designed forblowout prevention to prevent the valve stem from ejecting from the valve bodydue to improper operation.

- Fully-welded ball valve alsohas a fire and anti-static device.

- In order to drain the ballvalve, the drain valve and vent valve are respectively installed on the valvebody. Then the isolation valve or special discharge joint is adopted, which is saferand more reliable.

Inconclusion, compared with ordinary ball valves, fully-welded ball valves havehigher safety performance.

Fully-welded ball valves can also be equipped with a connecting padof various drive devices. The driving device includes lever, worm gear,electric, pneumatic, pneumatic-hydraulic, electro-hydraulic, etc.

|

|

DN50-DN1400 NPS 2” ~ NPS 56” |

|

|

PN20-PN420 Class 150LB—Class 2500LB |

|

|

WCB、LCB、CF8、CF8M、CF3、CF3M、A105、LF2、F304、F316、F304L、F316L |

|

|

API608、API 6D 、BS5351、ASME B16.34、GB/T12237、GB/T15672 |

|

|

ASME B16.10、GB/T12221、API 6D |

|

|

ASME B16.5、ASME B16.47、ASME B16.25、GB/T9113、JB/T79、HG/T70592 |

|

|

API 6D 、API 598、GB/T13927、GB/T26480 |

|

|

|

For more information, please visit http://www.raysvalve.cn/, or send an email to info@raysvalve.com, or call +86-577-66999000