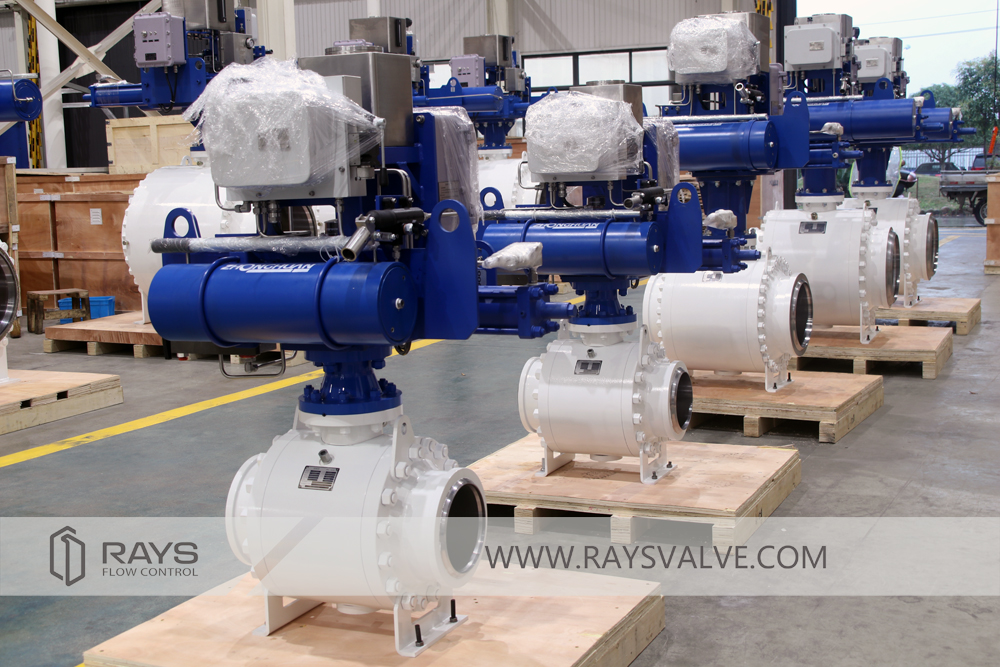

Recently, RAYS have successfully completed a DN150-DN1000 PN63 Gas-Over-Oil actuated ball valves project which have passed various tests. After debugging, these 17 pcs of ball valves and actuators have been delivered to our foreign customer in March of 2020 which will be placed in a large-scale booster compressor station project.

Due to the recent epidemic situation in China, under the advice of the local epidemic prevention team during early March, RAYS management and personnel department properly arranged the enterprise to resume work and production. RAYS have tried their best to shorten the impact of the delivery date for customers.

All the ball valves delivered this time adopted safety Gas-Over-Oil actuator with hydraulic manual and pneumatic functions, which are featured with remote control and ESD emergency shutdown functions. The customer only needs to provide 220V AC power supply on-site. In addition, the challenging characteristics of the products in this order were: large diameter, high pressure, high height of the whole setup, the largest single piece of the DN1000 ball valve weighed about 15 tons, production equipment, lifting equipment, debugging equipment, and personnel safety production. In the early stage of order production RAYS held: production seminars, process seminars, safety production training sessions for personnel, debugging training sessions for executing agencies, and other ways to ensure the smooth progress of the order. Also, RAYS held reasonable time planning and procurement of the corresponding supporting equipment to ensure the production efficiency of the order and the stringent testing requirements of the valves.

The products of this order have two different designs of ball valves: bolted body connection and fully welded body. Before installation of the actuator, in order to ensure that the torque of the ball valve is within the theoretical calculation range, there is a need to detect the torque value of the ball valve before the actuator debugging. Fortunately, RAYS is also equipped with a special automated computer torque detector for situations such as this.

The excellent quality and high-performance stability of the fully welded ball valve is not achieved by the normal ball valve. Therefore, the service life of the fully welded ball valve far exceeds the normal ball valve. In this instance, it is used very widely in various fields such as: urban gas, urban heating, petrochemical, ship-building, steel, pressure control station, power plant, and other types of pipeline equipment. Fully welded ball valves can be: long-term, stable operation, easy installation, lower cost of the expenditure, etc. In the foreseeable future, the fully welding process will become a trend in valve manufacturing.

For more information, please visit https://www.raysvalve.com/, or send an email to info@raysvalve.com